Whitepapers

Servo Motors

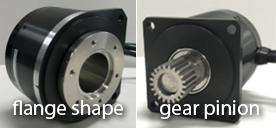

Customizing your micro direct-drive servo motor

When manufacturing a new product on a large scale, likely it makes sense to make sure every aspect of the motor is designed specifically to meet your and your customers' needs. Here are two reasons to consider customization.

When manufacturing a new product on a large scale, likely it makes sense to make sure every aspect of the motor is designed specifically to meet your and your customers' needs. Here are two reasons to consider customization.

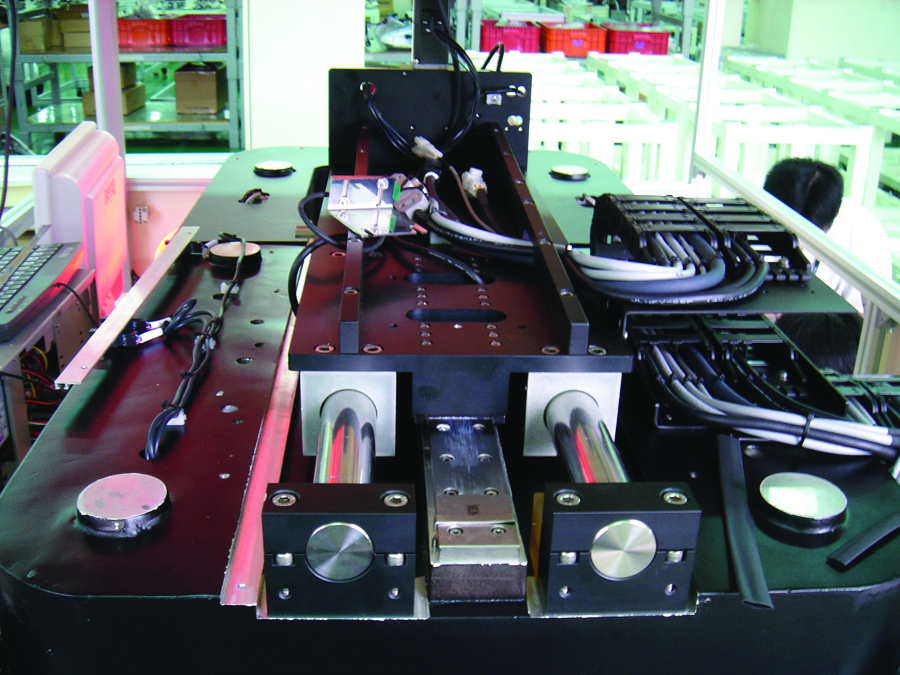

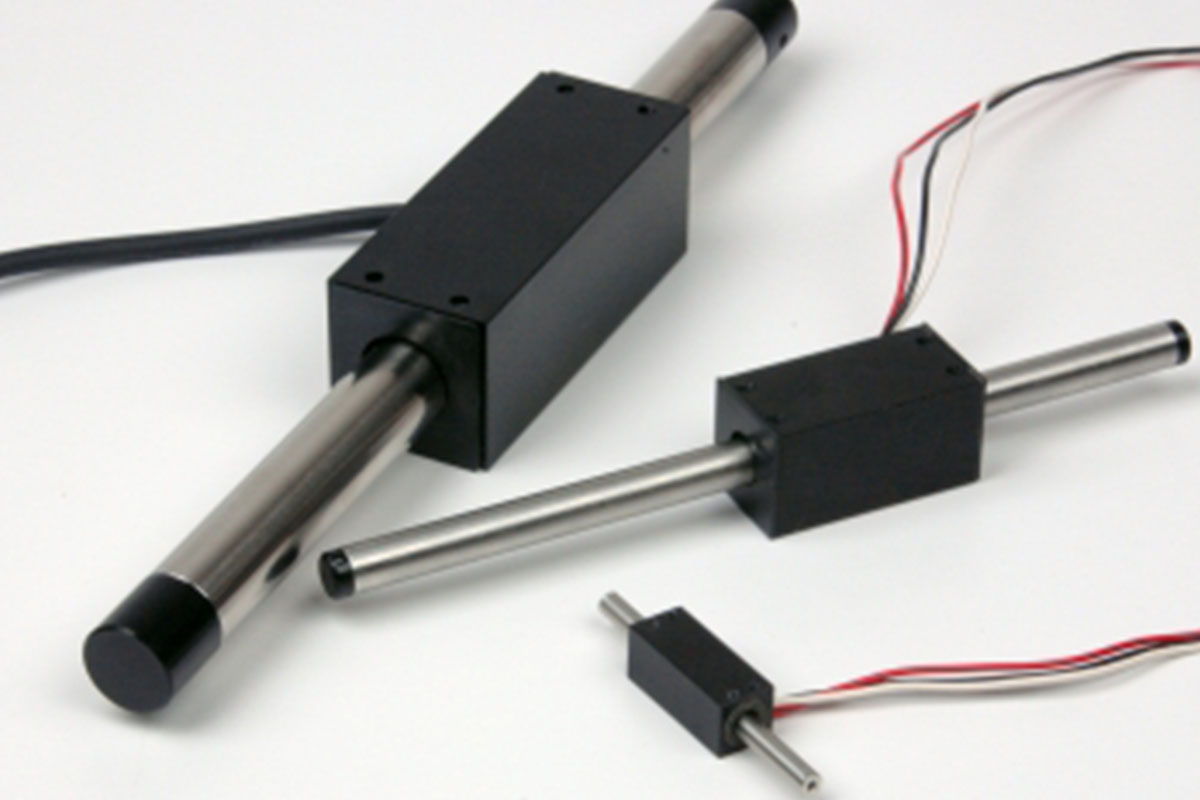

Linear Shaft Motors in Semiconductor Applications

Linear Shaft Motor servos are somewhat unknown in the machine builder market; they have usually been embedded deep within high-precision OEM systems that handle lithography, wafer scanning, and optical inspection applications. However, in the area of semiconductor automation, they are the motor of choice due to their ultra-precise capabilities. Here are a few of the benefits of using Linear Shaft Motors for semiconductor manufacturing.

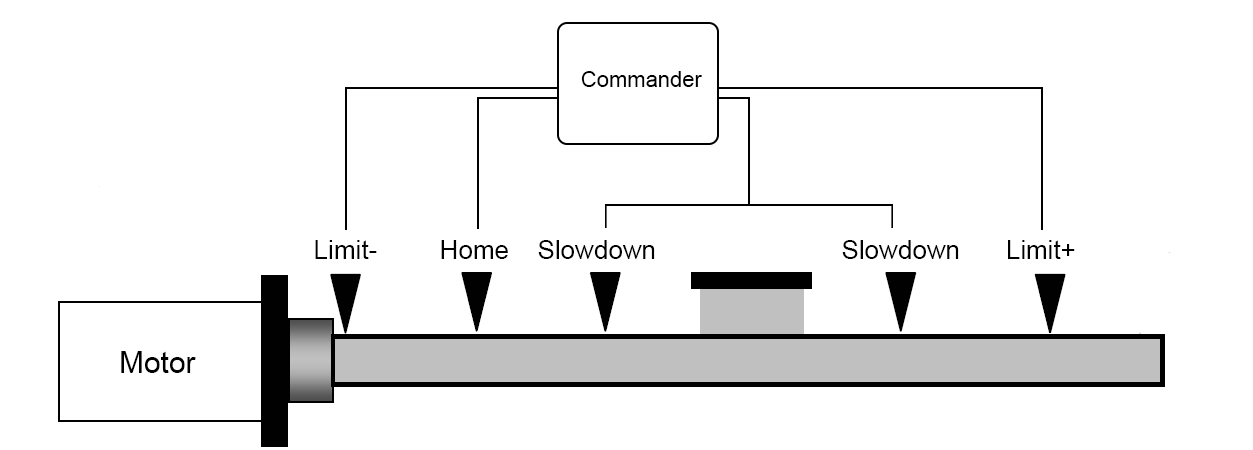

Building a motion control system: Limit switches and circuit considerations

Every motion control system will have specific limits where motion should occur. When a motion system has a specific “safe” range of motion, limit switches are often used to restrict the motion to keep it in the safe range.

Every motion control system will have specific limits where motion should occur. When a motion system has a specific “safe” range of motion, limit switches are often used to restrict the motion to keep it in the safe range.

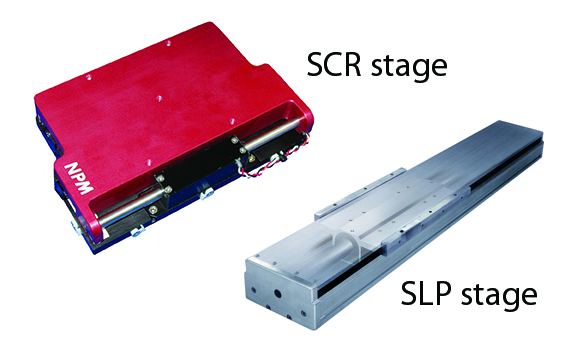

Which type of linear stage should I choose?

Nippon Pulse offers two series of high-performance, single-axis linear stages: nanopositioning SCR stages, and Acculine SLP stages. Both series are ideal for small-scale or limited-space applications, and provide an excellent introduction to our Linear Shaft Motor servos, the basis for all of Nippon Pulse’s stages. Click to learn about the different features of each stage series and their mechanical differences.

Nippon Pulse offers two series of high-performance, single-axis linear stages: nanopositioning SCR stages, and Acculine SLP stages. Both series are ideal for small-scale or limited-space applications, and provide an excellent introduction to our Linear Shaft Motor servos, the basis for all of Nippon Pulse’s stages. Click to learn about the different features of each stage series and their mechanical differences.

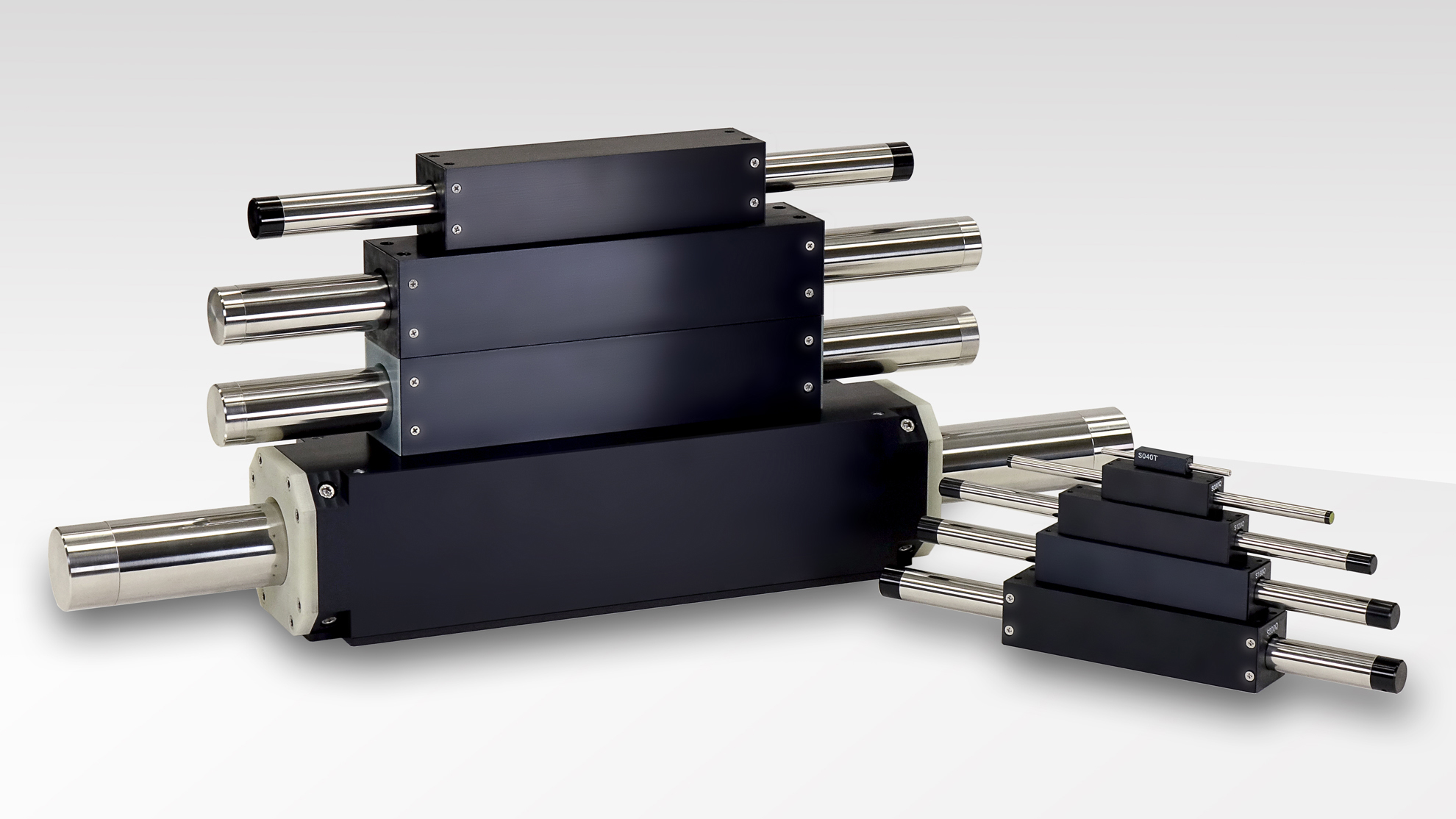

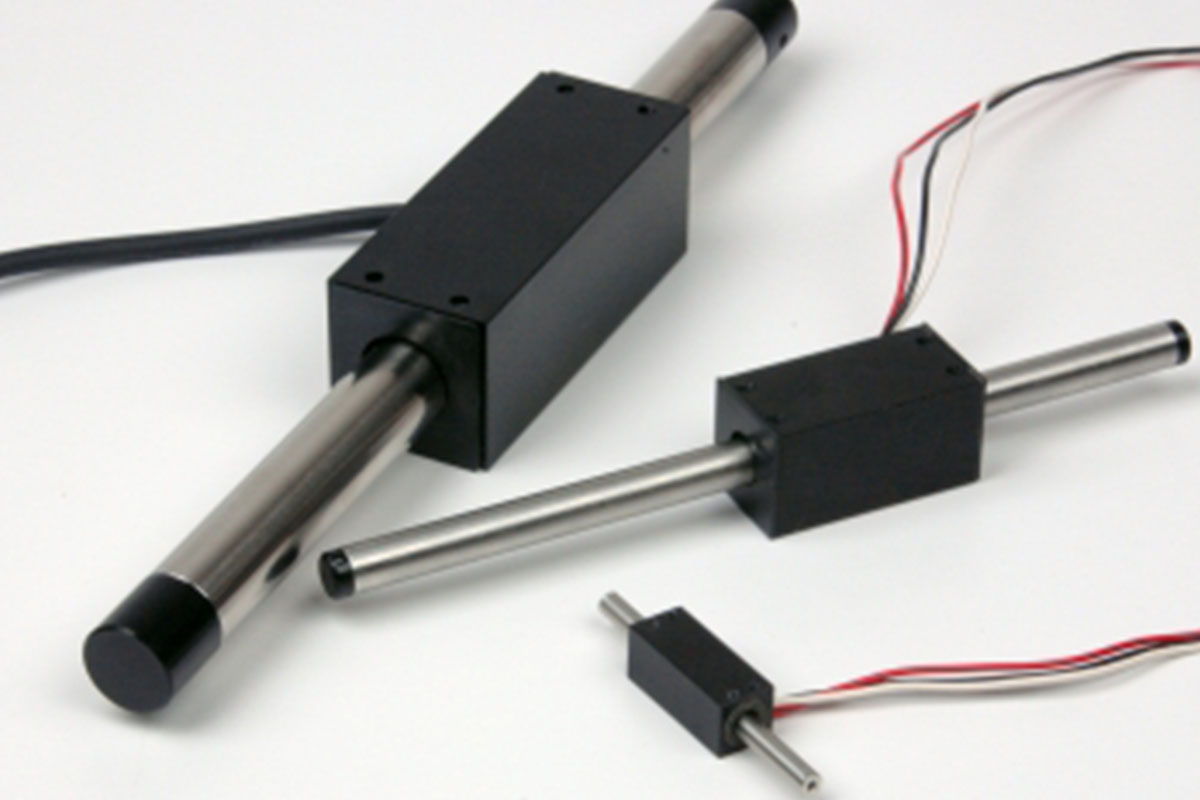

Linear Shaft Motors and Actuators: the secret weapon OEM engineers don't know they have

Linear shaft motors are a permanent-magnet-based technology to generate linear motion in one axis. They are relatively simple to build, design and integrate, and their extremely high reliability and increasing power density make them excel in an array of automated machines. In this article we answer four frequently asked questions about linear shaft motors.

Linear shaft motors are a permanent-magnet-based technology to generate linear motion in one axis. They are relatively simple to build, design and integrate, and their extremely high reliability and increasing power density make them excel in an array of automated machines. In this article we answer four frequently asked questions about linear shaft motors.

Servo Motor Terminology FAQ: What's the difference between an industrial servo motor and a hobbyist-quality servo motor?

Nippon Pulse engineers are regularly approached by hobbyists and educators looking for servo motors. But there is a big difference between wshat these novice engineers are usually seeking — two-lead dc motors — and precision industrial servo motors run off ac power with an encoder for feedback. We look at the terminology for both market segments and make sense of servos.

Nippon Pulse engineers are regularly approached by hobbyists and educators looking for servo motors. But there is a big difference between wshat these novice engineers are usually seeking — two-lead dc motors — and precision industrial servo motors run off ac power with an encoder for feedback. We look at the terminology for both market segments and make sense of servos.

Linear Shaft Motor servos and electronics to solve your machining problems

Design engineers run up against all kinds of issues when designing a new application – ensuring the motors meet force and size requirements, making sure the electronics to run the application are well-designed, and keeping costs down, just to name a few – and Nippon Pulse has made it our goal to help “ease the pain” of common machining concerns, with help from our patented Linear Shaft Motor and our dynamic electronics.

Design engineers run up against all kinds of issues when designing a new application – ensuring the motors meet force and size requirements, making sure the electronics to run the application are well-designed, and keeping costs down, just to name a few – and Nippon Pulse has made it our goal to help “ease the pain” of common machining concerns, with help from our patented Linear Shaft Motor and our dynamic electronics.

Configuring your Linear Shaft Motor system

The design of the Linear Shaft Motor allows you to replace the standard ball-screw system with the Linear Shaft Motor and achieve higher speed and resolution. However, to achieve the highest performance, the entire system structure must be optimized. This is a quick overview of options to consider when configuring your servo motor.

The design of the Linear Shaft Motor allows you to replace the standard ball-screw system with the Linear Shaft Motor and achieve higher speed and resolution. However, to achieve the highest performance, the entire system structure must be optimized. This is a quick overview of options to consider when configuring your servo motor.

Linear Shaft Motor vs. Other Linear and Rotary-to-Linear Technologies

A short overview of the benefits of using a Linear Shaft Motor servo in place of other popular linear motor options, as well as benefits over conventional rotary-to-linear systems.

A short overview of the benefits of using a Linear Shaft Motor servo in place of other popular linear motor options, as well as benefits over conventional rotary-to-linear systems.

Force-current relationship important when using linear motion for part production

-1200x800.jpg) A basic need of the machine design is to be able to go to a position, and knowing where that position is relative to the workpiece. In looking at achieving accuracy in the movement of a workpiece or the tooling, there are three areas of the machine design: the mechanical components, the command and control of the movement (control boards and servo loop), and the translation mechanism (linear motor or rotary motor and ball screw). This article is focused on one aspect of translation, specifically the force generated by linear electric motors.

A basic need of the machine design is to be able to go to a position, and knowing where that position is relative to the workpiece. In looking at achieving accuracy in the movement of a workpiece or the tooling, there are three areas of the machine design: the mechanical components, the command and control of the movement (control boards and servo loop), and the translation mechanism (linear motor or rotary motor and ball screw). This article is focused on one aspect of translation, specifically the force generated by linear electric motors.

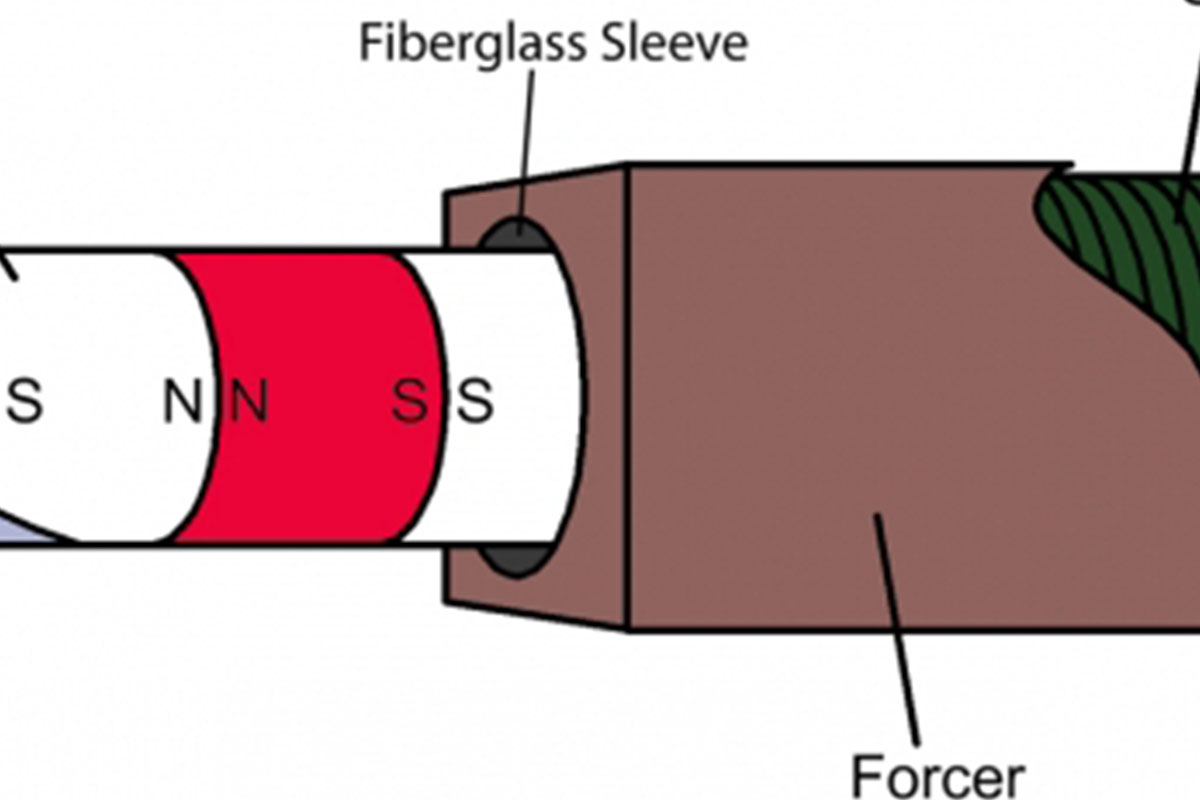

Linear Motor Systems: Iron Core, U-Channel and Tubular Linear Motors

There are three main direct drive linear motion systems on the market today. These three motor types have distinct advantages and disadvantages and, based on the application, one motor will be better suited than either of the other motors. This white paper will present the basic mechanism of operation of these three linear motors along with the advantages and disadvantages of each.

There are three main direct drive linear motion systems on the market today. These three motor types have distinct advantages and disadvantages and, based on the application, one motor will be better suited than either of the other motors. This white paper will present the basic mechanism of operation of these three linear motors along with the advantages and disadvantages of each.

Linear Shaft Motor 50 Percent More Efficient than Coreless Linear Servos

Linear motors have gained a name for themselves as being a high-precision and power-efficient alternative to conventional rotary-to-linear transmission systems. How is this possible? Well, let's look at the Ball Screw, which also can be considered, in its own right, a high precision rotary-to-linear transmission system. The Ball Screw is typically only 90 percent efficient[1]. When we add the efficiency of the servo motor (range from 75 to 80 percent[2]) and losses that will be introduced by the coupling (and if using a gear box), it is possible that only 55 percent of the power we are supplying is going towards work. When we compare the typical linear motor, where the motor is driving the load linearly, we can quickly see why the linear motor has gained a name as being more power-efficient.

Linear motors have gained a name for themselves as being a high-precision and power-efficient alternative to conventional rotary-to-linear transmission systems. How is this possible? Well, let's look at the Ball Screw, which also can be considered, in its own right, a high precision rotary-to-linear transmission system. The Ball Screw is typically only 90 percent efficient[1]. When we add the efficiency of the servo motor (range from 75 to 80 percent[2]) and losses that will be introduced by the coupling (and if using a gear box), it is possible that only 55 percent of the power we are supplying is going towards work. When we compare the typical linear motor, where the motor is driving the load linearly, we can quickly see why the linear motor has gained a name as being more power-efficient.

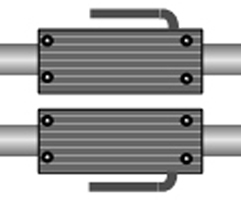

Linear Shaft Motors in Parallel

With the Linear Shaft Motor, you have the ability to drive two motors in parallel using only one encoder and one amplifier. All other systems require two drives, two controllers and two encoders, connected together. How is the Linear Shaft Motor able to overcome these issues?

Stepper Motors

Closing the Loop: Stepper Motors Operating in Servo Mode

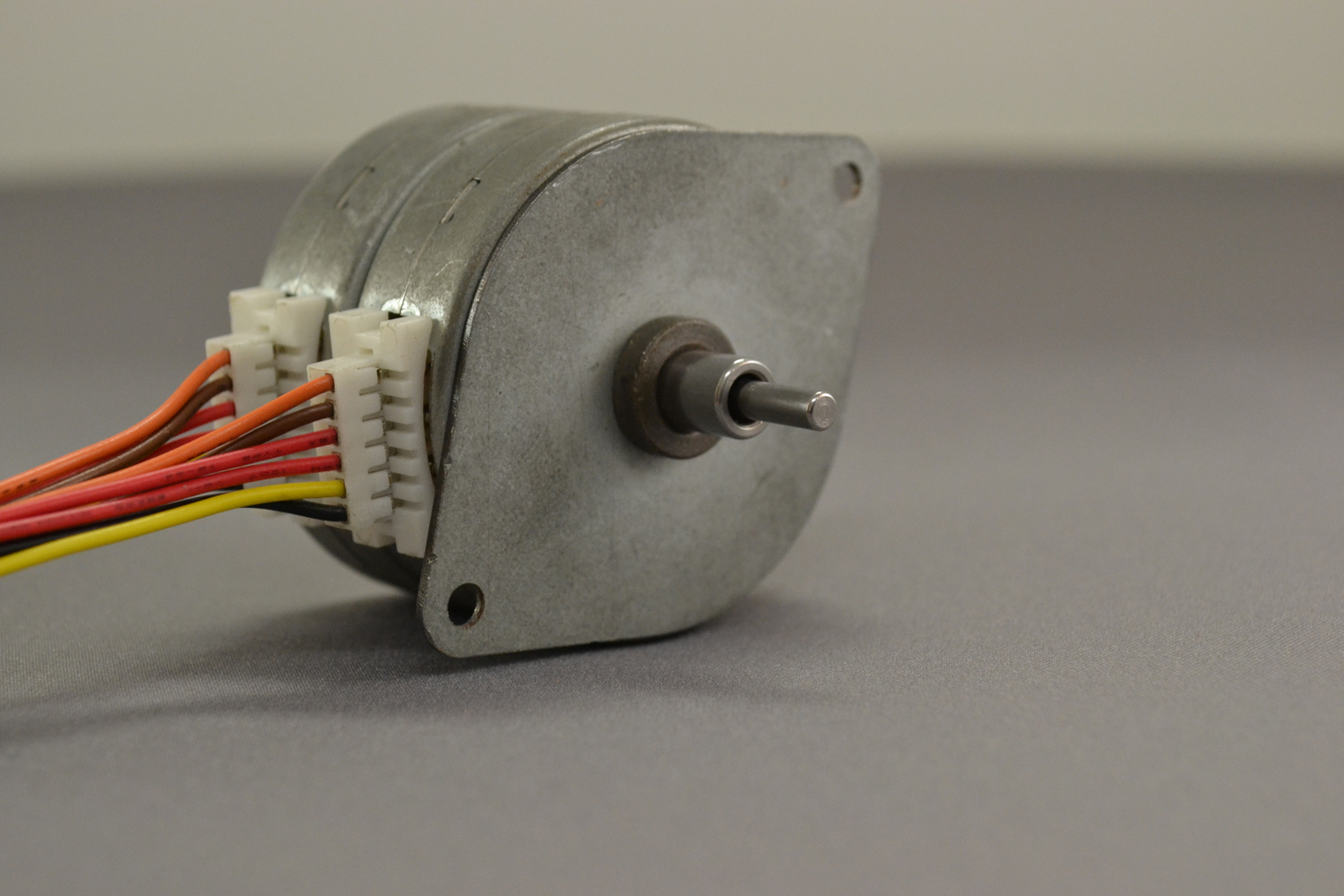

Running a stepper motor in servo mode is a bit of a new thing. In the past, when talking about utilizing rotary servo motion, that meant using a brushless servo motor; however, if you have an encoder with sufficient resolution and a servo driver, you can control a rotary stepper motor to achieve the same motion profile. In this article, we will review what it means to operate a stepper open loop and discuss why it is sometimes beneficial to break with habit to operate in closed loop.

Running a stepper motor in servo mode is a bit of a new thing. In the past, when talking about utilizing rotary servo motion, that meant using a brushless servo motor; however, if you have an encoder with sufficient resolution and a servo driver, you can control a rotary stepper motor to achieve the same motion profile. In this article, we will review what it means to operate a stepper open loop and discuss why it is sometimes beneficial to break with habit to operate in closed loop.

3 Reasons to Customize a Stepper Motor

In today’s competitive marketplace, a major factor for machine builders is still keeping costs low, but also ensuring a competitive advantage over other machine builders. Reaching that peak optimization may mean forgoing mass-produced motors, and instead looking at customization options. Here are three reasons it makes sense to consider going custom.

In today’s competitive marketplace, a major factor for machine builders is still keeping costs low, but also ensuring a competitive advantage over other machine builders. Reaching that peak optimization may mean forgoing mass-produced motors, and instead looking at customization options. Here are three reasons it makes sense to consider going custom.

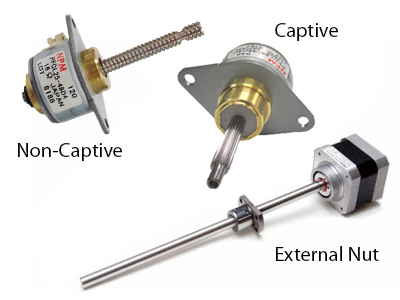

What's the difference between captive and non-captive linear steppers?

There are three mechanical configurations to choose from for linear stepper motors: captive, non-captive, and external nut. In this whitepaper we review all three and discuss the differences in their housing, shafts, and other external characteristics, as well as discuss the best configuration based on application requirements.

There are three mechanical configurations to choose from for linear stepper motors: captive, non-captive, and external nut. In this whitepaper we review all three and discuss the differences in their housing, shafts, and other external characteristics, as well as discuss the best configuration based on application requirements.

The four torque characteristics associated with stepping motors

When choosing a stepper motor, it is important to understand four torque characteristics: pull-out torque, pull-in torque, holding torque and detent torque.

When choosing a stepper motor, it is important to understand four torque characteristics: pull-out torque, pull-in torque, holding torque and detent torque.

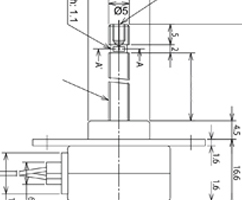

Extreme customization, well-maintained tooling and accuracy

An OEM small-batch manufacturing customer came to Nippon Pulse because their current supplier’s motors had a very high failure rate for the newest generation version of their application. The new generation required accuracy from the motor that 50 percent of the delivered motors could not meet. The customer contacted us and requested a sample to evaluate, which – when tested – was well within their resolution and accuracy requirements.

An OEM small-batch manufacturing customer came to Nippon Pulse because their current supplier’s motors had a very high failure rate for the newest generation version of their application. The new generation required accuracy from the motor that 50 percent of the delivered motors could not meet. The customer contacted us and requested a sample to evaluate, which – when tested – was well within their resolution and accuracy requirements.

Controllers

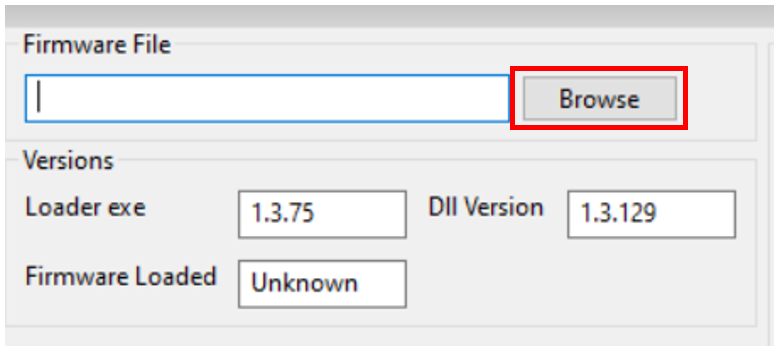

Firmware 101: What is it, why do I need it, and when should I update it?

You may or may not have heard the term "firmware" before. However, if you own any modern electronic device, you use firmware. But what does this term mean?

You may or may not have heard the term "firmware" before. However, if you own any modern electronic device, you use firmware. But what does this term mean?

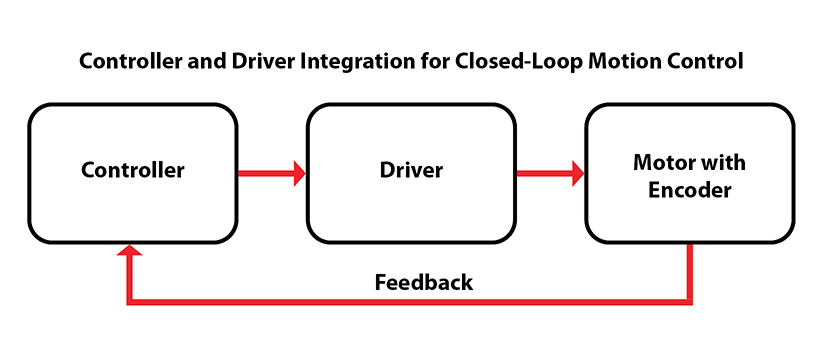

What’s the difference between a motion controller and a driver?

There are numerous terms that float around the motion control world and they can sometimes be confusing. It also can be quite unnerving to design a motion controller into a machine platform only to realize later that another component is needed to actually drive the motors. Let’s clear up the terminology of what a controller and driver each refers to.

There are numerous terms that float around the motion control world and they can sometimes be confusing. It also can be quite unnerving to design a motion controller into a machine platform only to realize later that another component is needed to actually drive the motors. Let’s clear up the terminology of what a controller and driver each refers to.

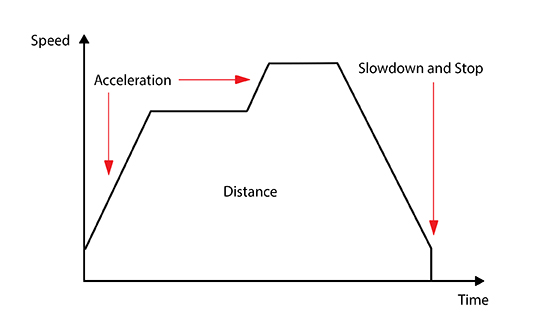

Motion Control Basics: What is a motion profile?

A motion profile is a two-dimensional visual plot of the operation of a motor. All sorts of combinations can be derived based on the needs of the application.

A motion profile is a two-dimensional visual plot of the operation of a motor. All sorts of combinations can be derived based on the needs of the application.

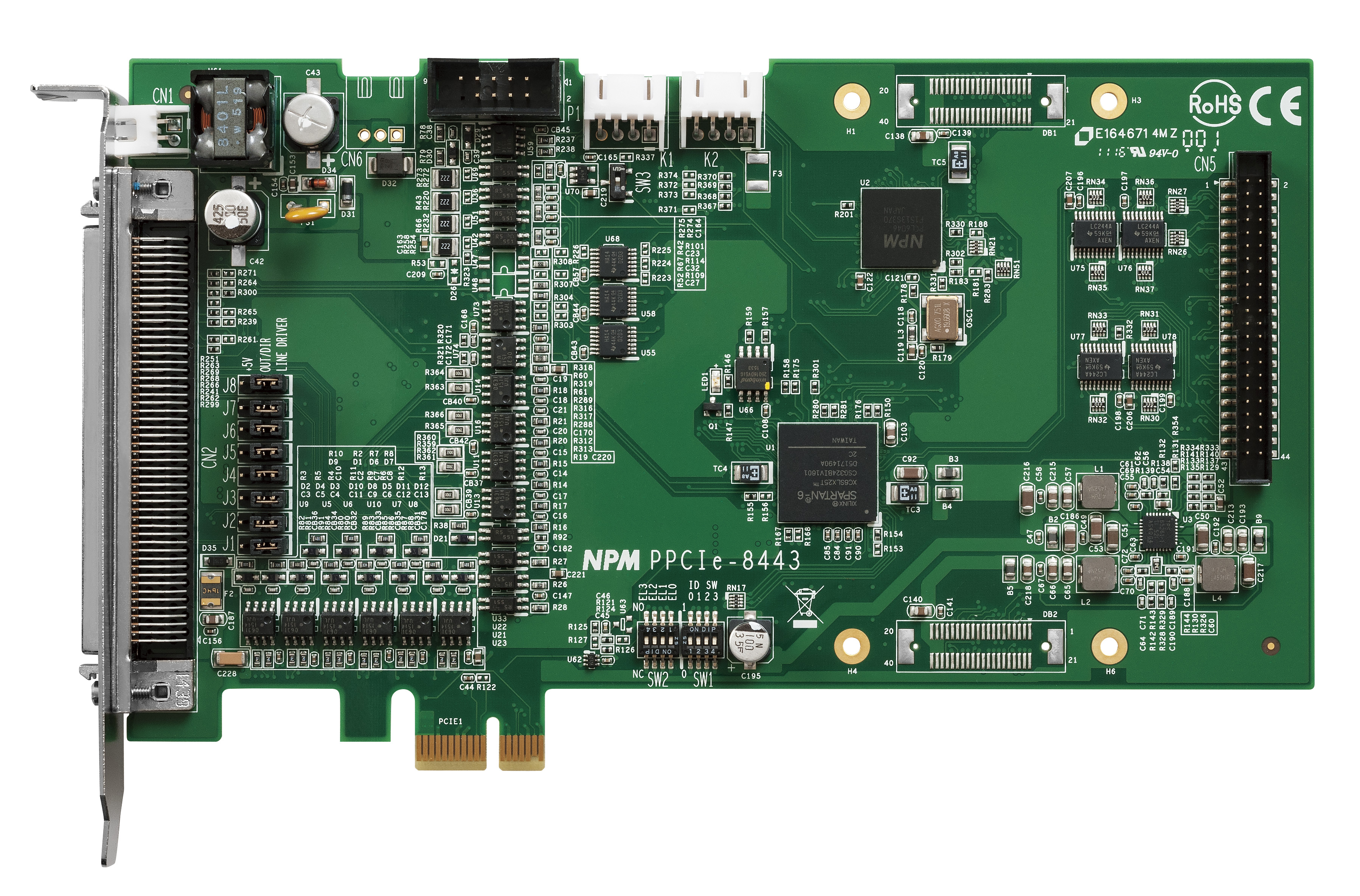

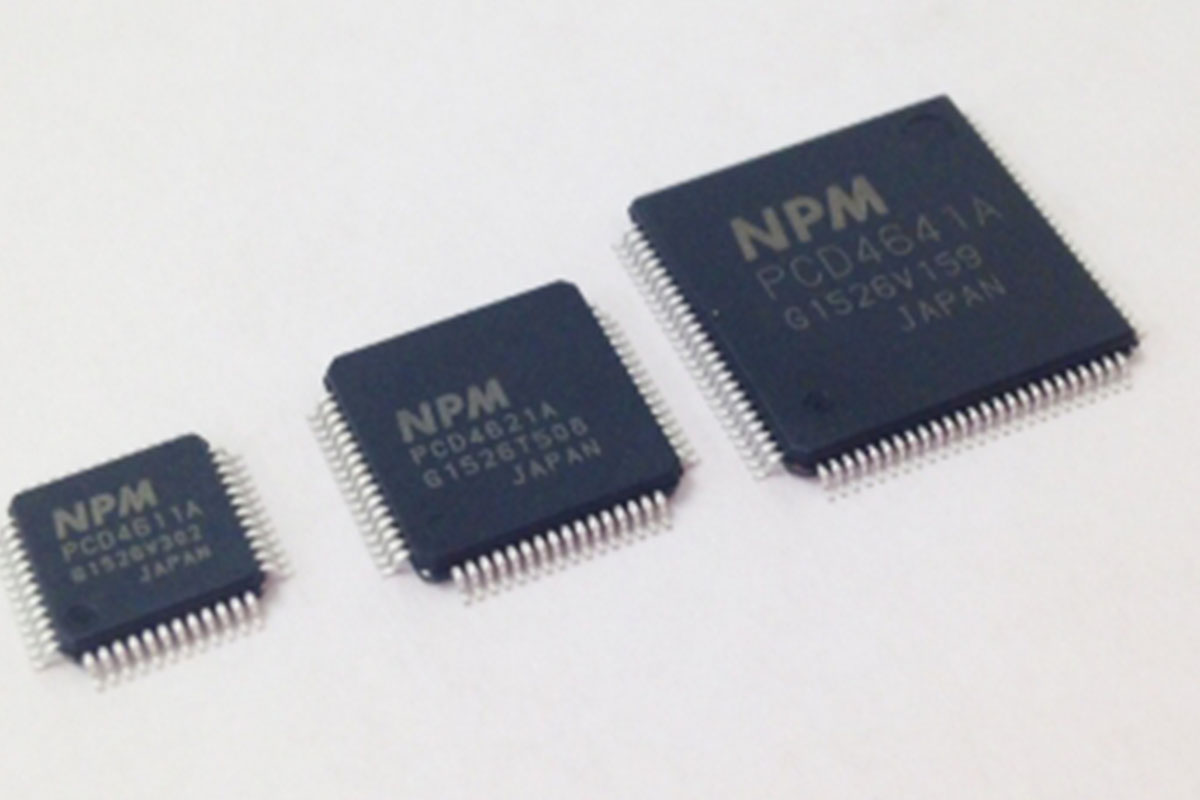

Controller chips' variety of origin return sequences

Origin return (or built-in homing) allows the controller to move the motor back to its initial, or starting, position. Every Nippon Pulse controller chip, in each of the four series, has multiple origin return sequences available, though the specific types of return modes available are dependent on the model.

Origin return (or built-in homing) allows the controller to move the motor back to its initial, or starting, position. Every Nippon Pulse controller chip, in each of the four series, has multiple origin return sequences available, though the specific types of return modes available are dependent on the model.

4 steps to choosing a motion controller

A simple-to-follow graphic on the considerations required to choose any motion controller for your application.

A simple-to-follow graphic on the considerations required to choose any motion controller for your application.

How to choose a servo controller for your application

When it comes to developing a new application, you have many options for control: all-in-one controller boxes, integration-ready boards, and ASIC chips for complete customization. What factors should be taken into consideration when selecting a motion controller option?

When it comes to developing a new application, you have many options for control: all-in-one controller boxes, integration-ready boards, and ASIC chips for complete customization. What factors should be taken into consideration when selecting a motion controller option?

Using a Dedicated Pulse Control LSI vs. a CPU for Motion Control

In order to operate a motor, you need a device or circuit that produces a speed and direction signal. In many cases, a CPU or FPGA device is used to create movement, because technically these devices can be programmed to generate pulses. However, no serious engineer should consider using these for important motion control applications, unless they are okay with a "good enough" mentality when it comes to their application's movement.

In order to operate a motor, you need a device or circuit that produces a speed and direction signal. In many cases, a CPU or FPGA device is used to create movement, because technically these devices can be programmed to generate pulses. However, no serious engineer should consider using these for important motion control applications, unless they are okay with a "good enough" mentality when it comes to their application's movement.

A pulse control LSI (motion control IC, ASIC) is a dedicated chip that is specialized for motion control. It is very easy to design programs when you use a convenient motion control-specific tool like a pulse control LSI. By choosing a pulse control LSI, you can easily write setting data and commands for both linear and S-curve acceleration/deceleration without overloading the CPU. When you consider CPU and engineering resource costs, ease of use, and speed of development, the end user benefits greatly from the specialized motion control option.

Basics of Servomotor Control

This document explains the difference between a servomotor and a stepper motor when connected to a servo driver. It covers the terms used in controlling the pulse train that is supplied to the servomotor by a PCL series controller. It does not, however, explain the principles of operation or the design of the motors or drivers.