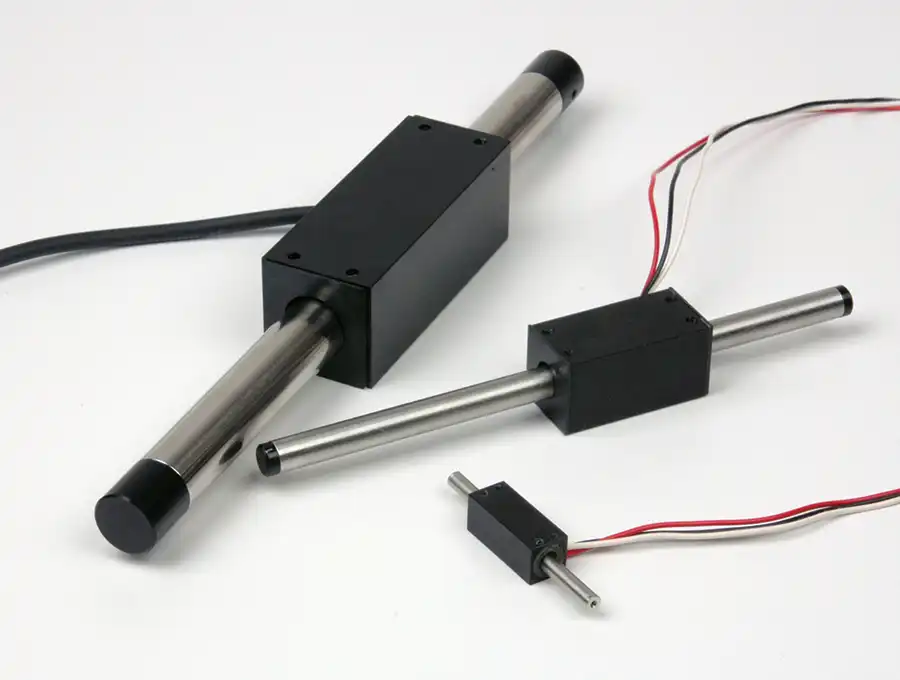

Linear Servo Motors

World's Largest Supplier of Linear Servo Motors

Linear motors come in a variety of technologies and styles, including brush or brushless, and configured as flat iron-core, U-shaped, or tubular. Nippon Pulse’s tubular Linear Servo Motor consists of a magnetic shaft and coil assembly (forcer) which can be integrated into a mechanical assembly and driven with a brushless DC servo drive. These linear motor actuators can replace ball and lead screw, pneumatic, and conventional flat or U-Channel linear actuation systems.

Specification Overview

- Range of shaft diameters: 4mm to 100mm

- Stroke lengths: 20mm to 4.6M

- Achievable peak forces more than 3000N

- Continuous force up to 600N

Linear Servo Motor Advantages

- Simplicity - The simple structure of a magnetic shaft and coil assembly (forcer) experiences minimal wear and is entirely maintenance-free, keeping your

machinery running longer with less downtime and a significant cost reduction throughout its lifespan. - Precision - With no iron in the forcer or shaft, ultra-high precision is achievable with zero cogging for applications that require extreme smoothness of

motion in machine operation. - Accuracy - High-performance positioning with encoder resolutions less than 10nm enable a positioning accuracy of ±1.2 pulses of encoder resolution for

improved yield of high precision processes. - Strength - Rare-earth magnets, the strongest magnets available, add to the intensity of the magnetic field and thus allowing a small amount of current to

produce large amounts of force for low power and high efficiency machines. - Speed - Able to efficiently move large amounts of weight accurately and smoothly at high speeds, increasing throughput and profitability.

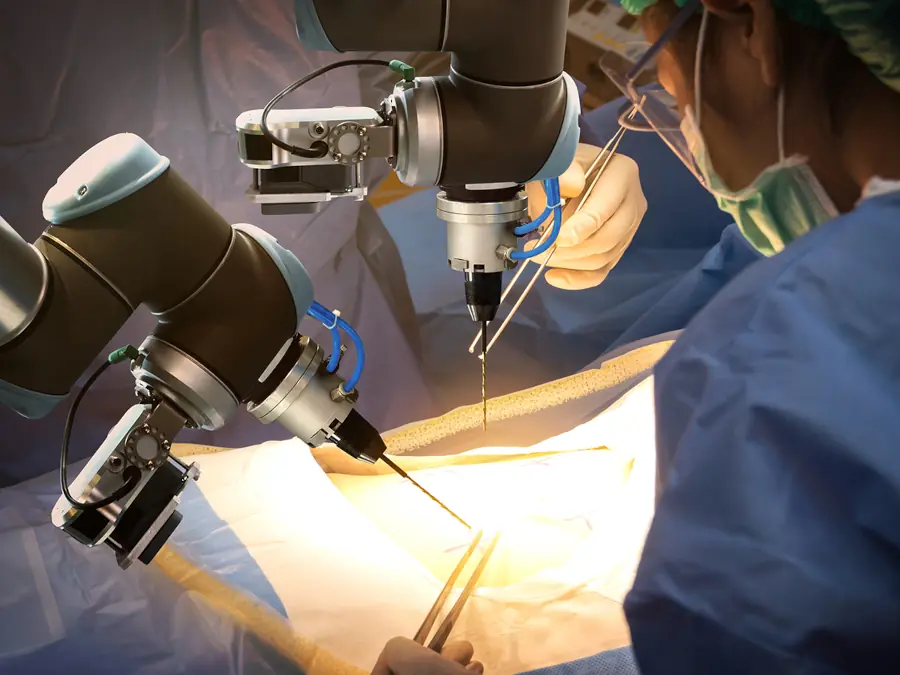

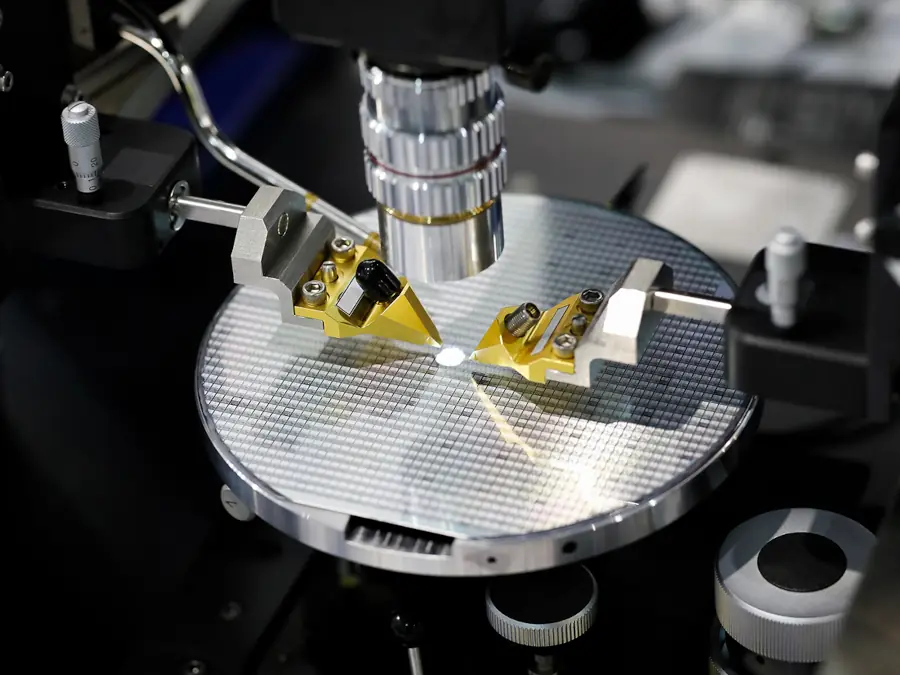

Precision Solutions for Industries

- Packaging

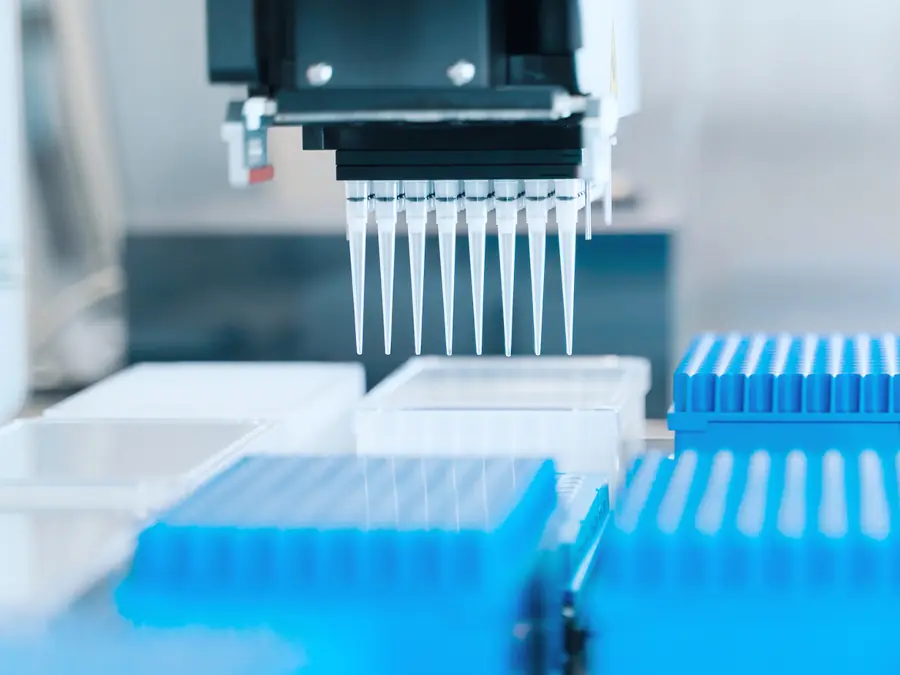

- Life Sciences

- Semiconductor

- Optics & Photonics

- Robotics

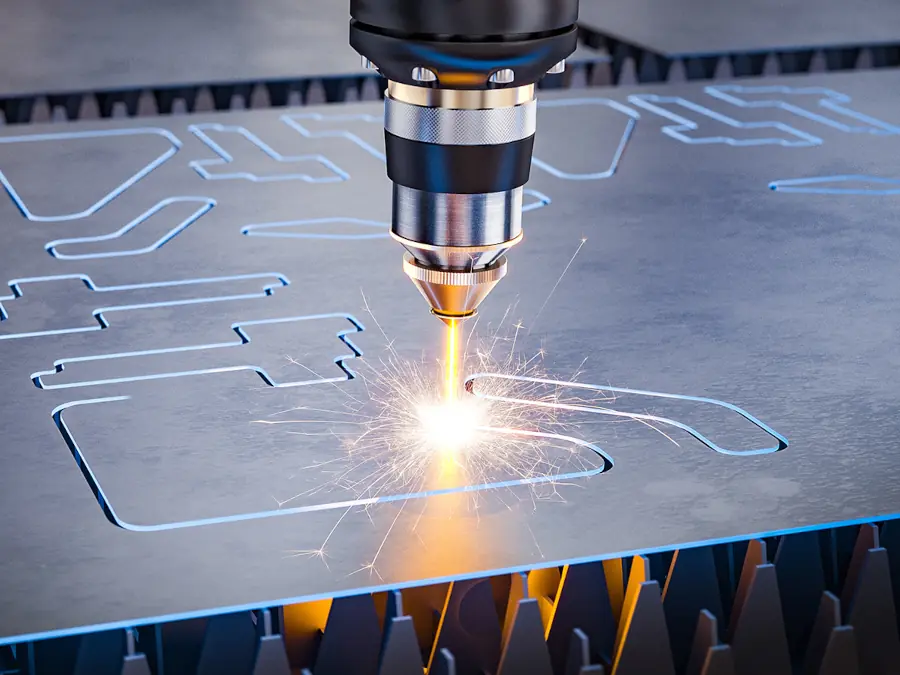

- Toolless Cutting

- Lab Automation

- Pharmaceuticals

How to Select the Best Linear Servo Motor Actuator for your Application

- Outline the motions that you’re trying to achieve

- Find the acceleration traverse and deceleration times need for each movement

- Specify the time between each movement

- Average the force/current needed for all of the moves (RMS average)

- Find a shaft motor with an RMS Force or RMS current larger than what is needed for your move

- Find a power supply and amplifier that can provide the currents needed for your moves (peak and RMS currents)

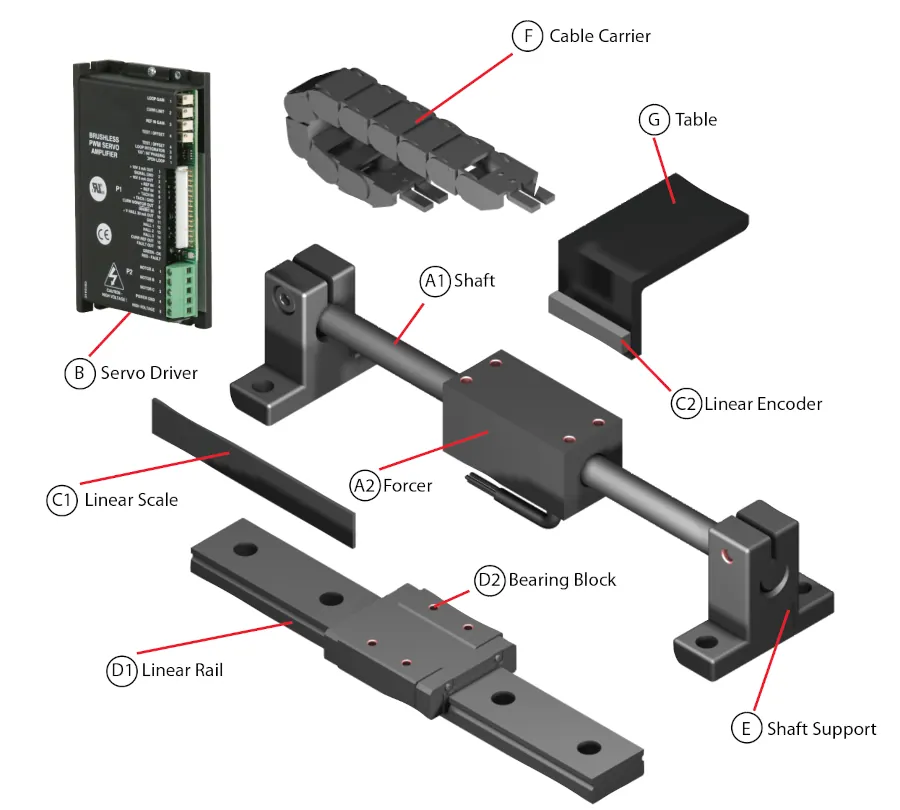

How to Configure a Linear Servo Motor

To configure a system using the Linear Servo Motor, the following peripheral devices are

required:

A1. Linear Servo Motor Shaft – Stainless steel Shaft with embedded magnets

A2. Linear Servo Motor Forcer – Motor coils and hall effects (optional)

B. Servo Driver – Servo amplifier to commutate and control the linear motor

C1. Linear Encoder Scale (optical or magnetic) – Feedback scale

C2. Linear Encoder Read Head – Feedback sensor

D1. Linear Rail – profile or round rail to support the forcer

D2. Linear Bearing Block – Attaches forcer to the bearing rails

E. Shaft Support – used to support the shaft

F. Cable Carrier – supports the cables that mover\ with the forcer

G. Table or Load Plate – mounting surface for the load

Item D1, D2 (Linear Guide) are a necessary part of a system, and must be selected based on the specific application requirements, environmental conditions, and fitted appropriately to the moving element (forcer or shaft).