Rotary Servo Motors

Ultra Light and Compact Direct Drive Motors

Nippon Pulse’s micro rotary AC servomotors are the world’s smallest, lightest direct drive motors! The compact unit features an integrated incremental or absolute feedback device, for accuracy and precision for positioning applications.

Specification Overview

- Frame sizes between 13mm and 70mm, with each size available in three stack lengths

- Optional hollow shaft configuration

- Built-in high-resolution absolute or incremental encoder

- Continuous torque 3.0 mNm to 1000 mNm, with peak ratings from 7 mNm to 3100 mNm

- Clean-room ready

Rotary Servo Motor Advantages

- Eliminates backlash and compliance for improved system bandwidth

- Easily backdrivable for high force sensitivity and impact resistance

- Compact, power dense design to minimize space requirements

- Eliminate gears, belts and pullies for reduced parts count, cost savings

- Fast move and settle times for increased productivity

- Quiet operation (<30dB at rotation)

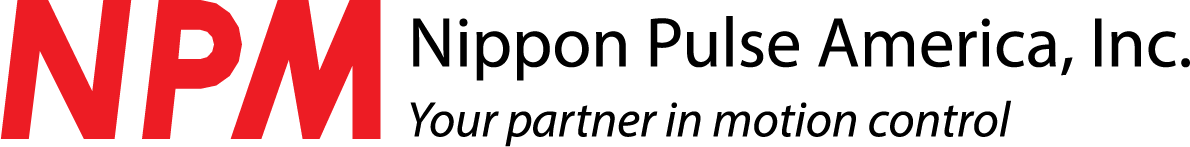

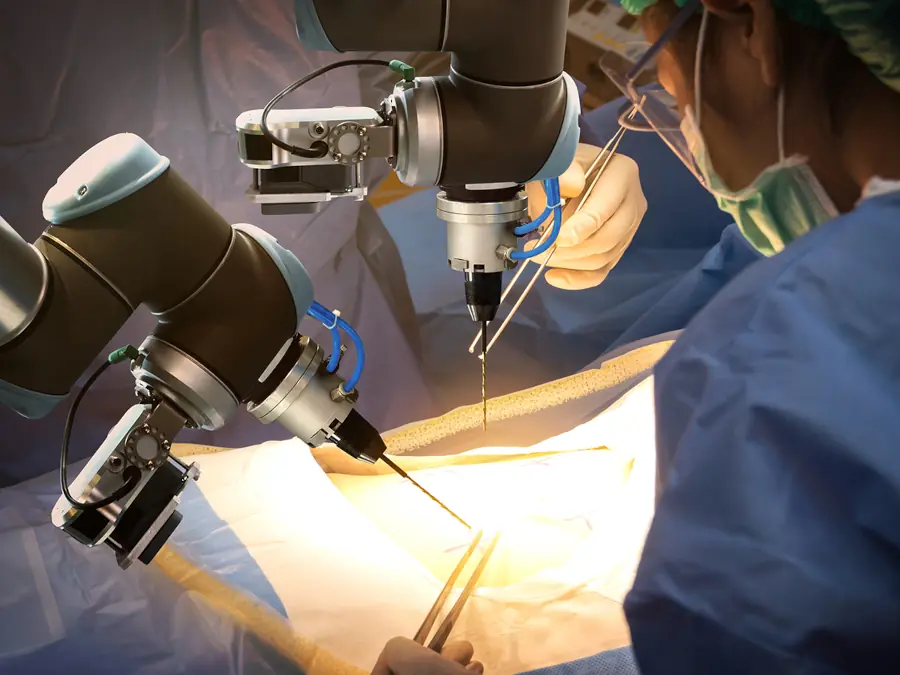

Precision Solutions for Industries

- Packaging

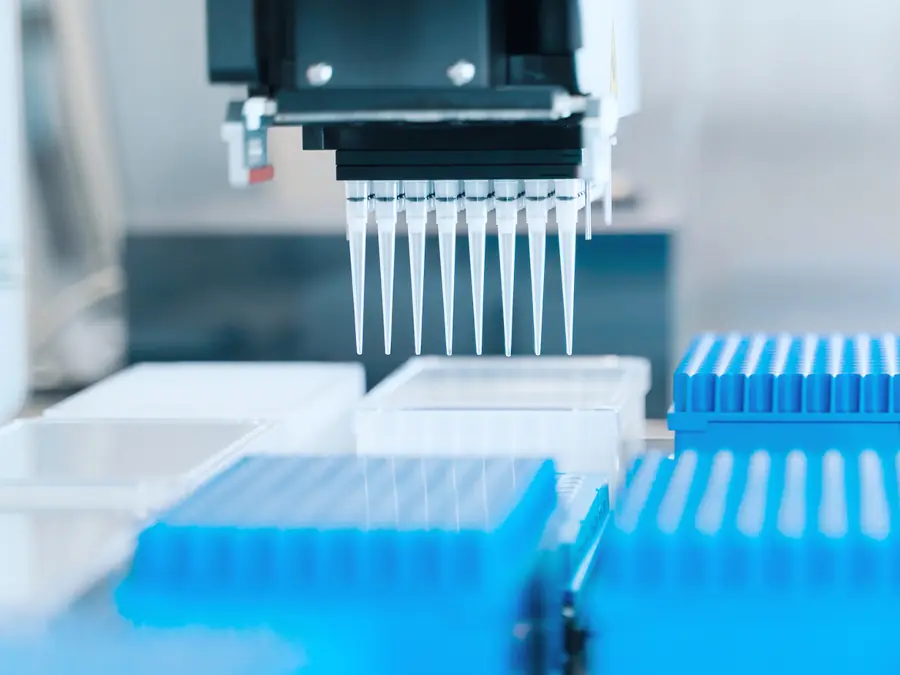

- Life Sciences

- Semiconductor

- Optics & Photonics

- Robotics

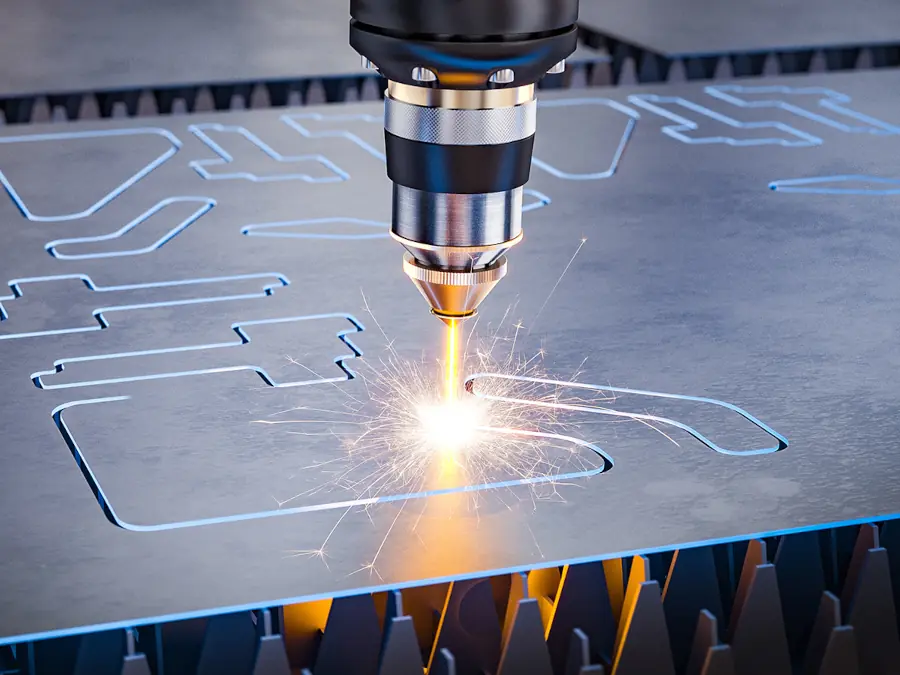

- Toolless Cutting

- Lab Automation

- Pharmaceuticals

Select the Best Rotary Servo Motor for your Application

1. Outline the motions that are required for the application

2. Determine the acceleration, traverse, and deceleration times needed for each movement

3. Calculate the torques required to move the payload based on the desired motion profile

4. Calculate the RMS torque and speed values

5. Find a motor that has a speed-torque curve that provides the torque required at each speed in your move profile and the RMS torque rating is less then the rated motor continuous torque

6. Select the correct electronics needed to drive the motor

Need a custom motor for your application? We build those to your exact specifications - click here to get started

Small, Miniature, and Micro Motor Solutions - click here to learn more