Rotary Stepper Motors

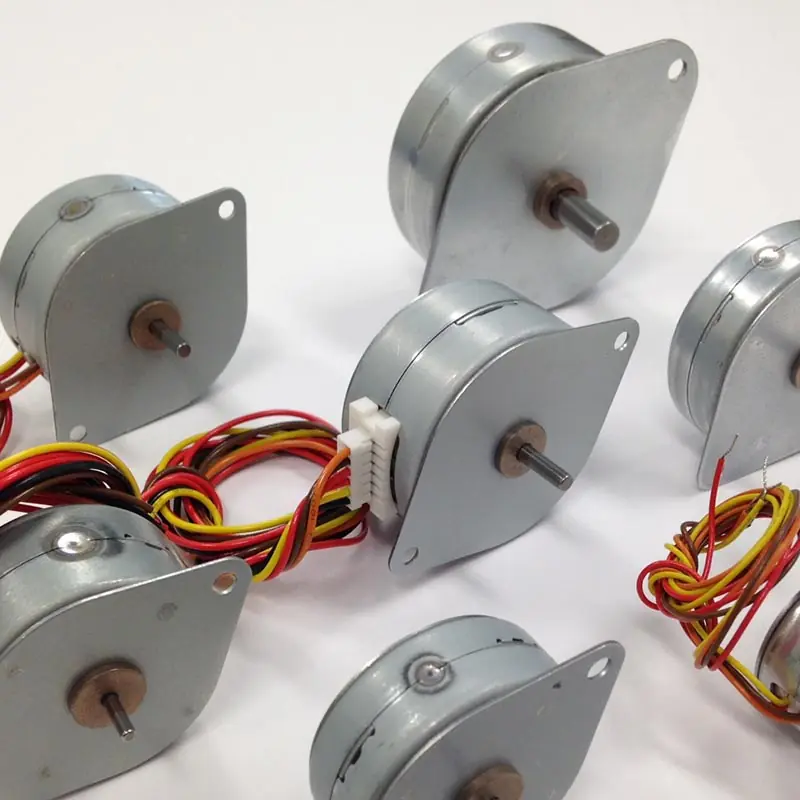

Rotary Tin Can Stepper Motors — High Performance and Cost-Effective

Since 1965, Nippon Pulse’s stepper motors have offered a cost-effective, high-performance solution for various medical, semiconductor, lab and industrial automation applications. Stepper motors use input pulses to take proportional steps for positioning and/or speed control. Stepper motors are typically operated using drivers that control pulse and direction.

Specification Overview

- Several customization options available on all tin-can steppers

- Available with diameters from 10mm up to 55mm

- Holding torque between 1 and 180 mNm

- Rated voltage of 5V and 12V

- 24 or 48 steps per revolution

- Unipolar and bipolar windings

Rotary Stepper Motor Advantages

- Easily determined and controlled speed (speed = steps per revolution /pulse rate)

- Fine incremental moves without requiring a feedback encoder (open loop)

- Fast acceleration with non-cumulative positioning error

- Low speed/high torque characteristics without gear reduction

- Loads held in a stationary position without creating overheating

- Wide speed range

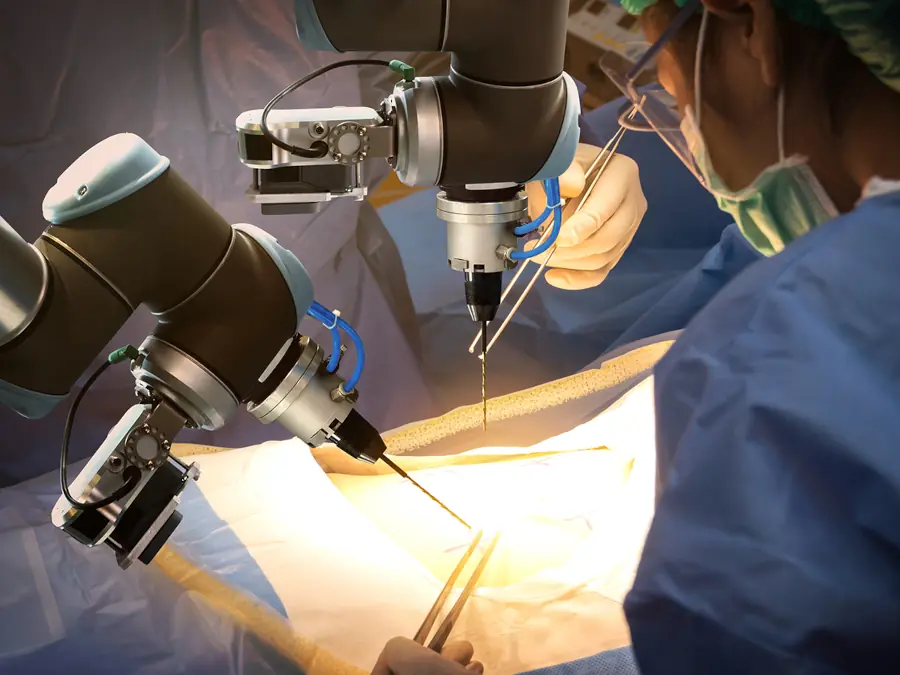

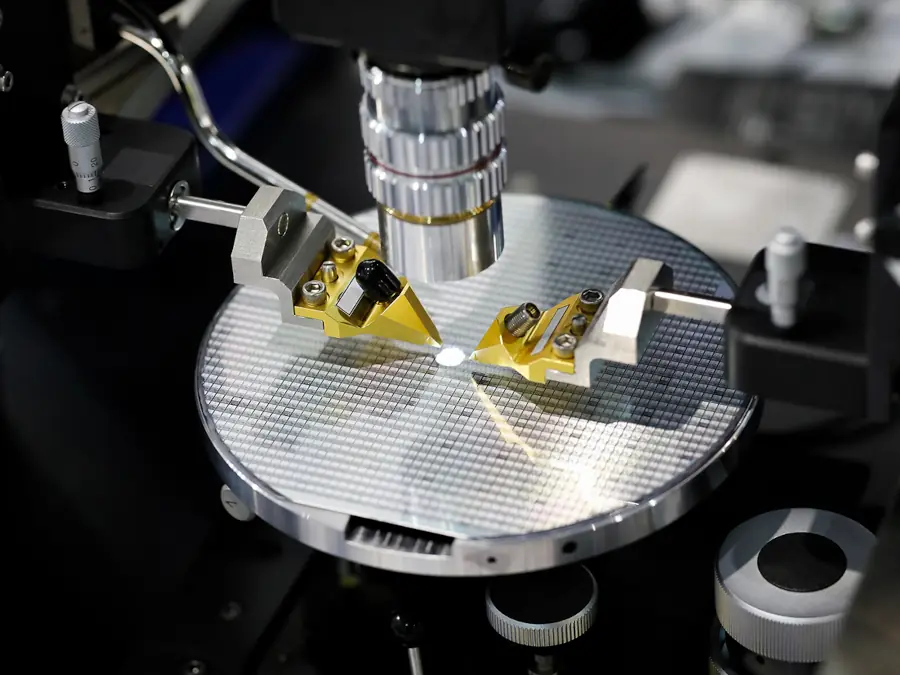

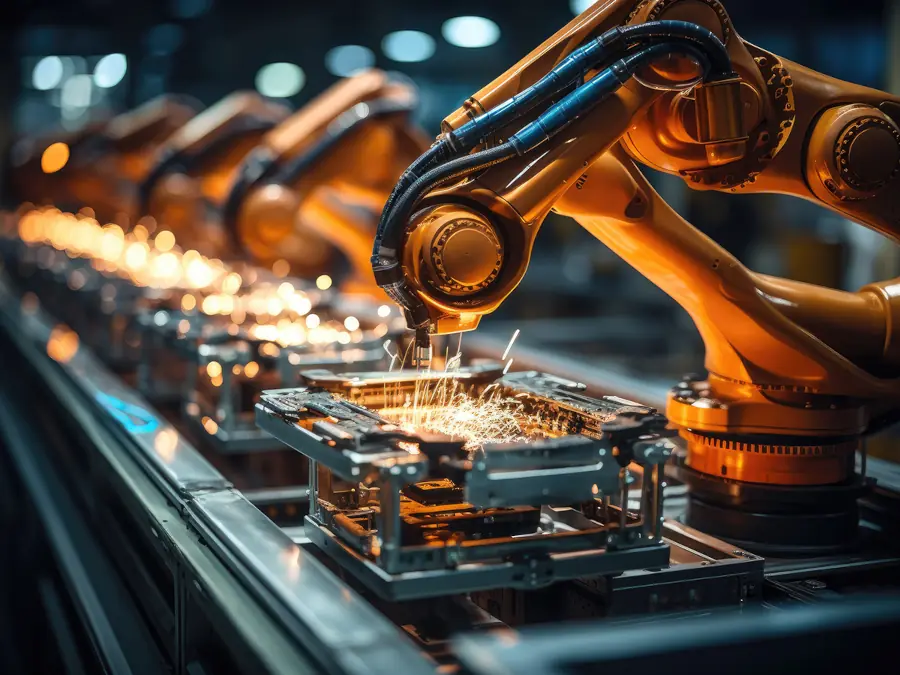

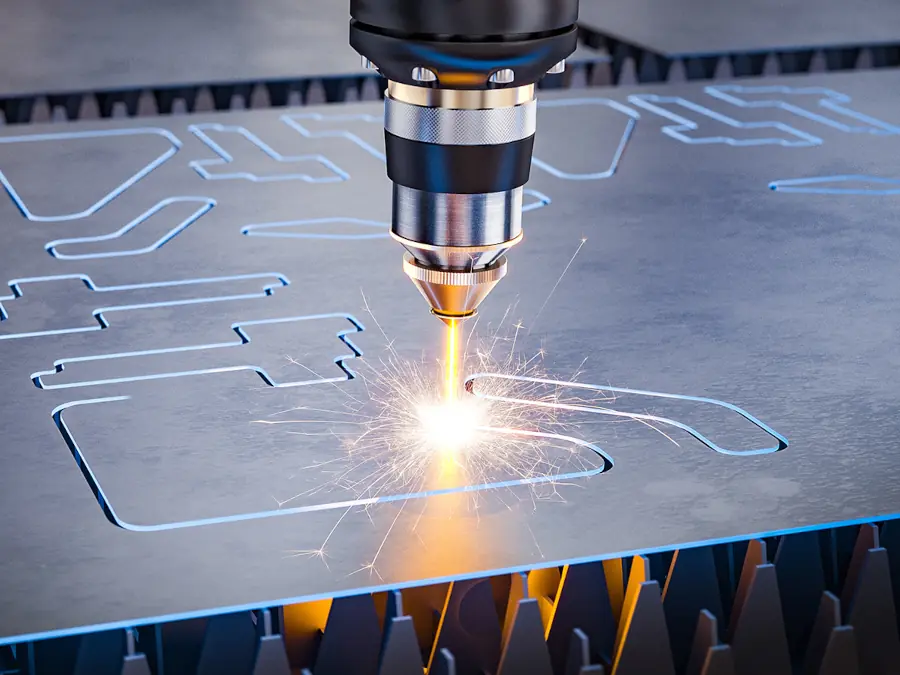

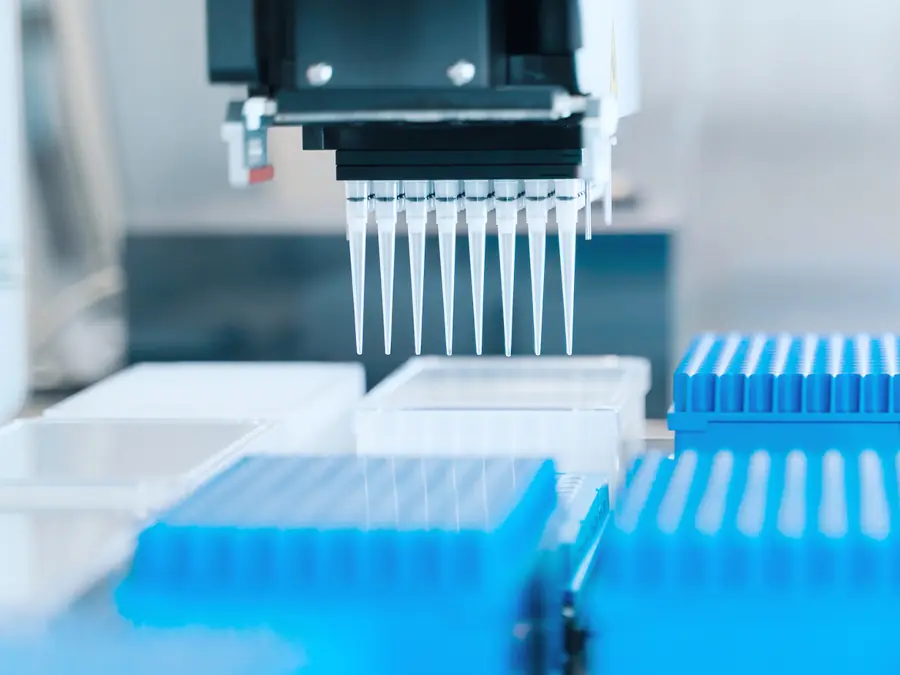

Precision Solutions for Industries

- Packaging

- Life Sciences

- Semiconductor

- Optics & Photonics

- Robotics

- Toolless Cutting

- Lab Automation

- Pharmaceuticals

Select the Best Rotary Stepper Motor for your Application

- Outline the motions that you’re trying to achieve

- Define the total number of degrees the motor will move

- Calculate the total number of steps in that movement

- Calculate the acceleration and deceleration needed to make the move in the time allowed

- Calculate the torque needed to accelerate and decelerate the payload

- Find a coil that has a torque curve that provides more force at each speed in your move than is needed to move the payload

- Select the correct electronics needed to drive the motor

Need a custom motor for your application? We build those to your exact specifications - click here to get started

Small, Miniature, and Micro Motor Solutions - click here to learn more