Semiconductor Solutions in Action

See us live at Semicon West — October 7-9, Booth 228

Check out these videos below

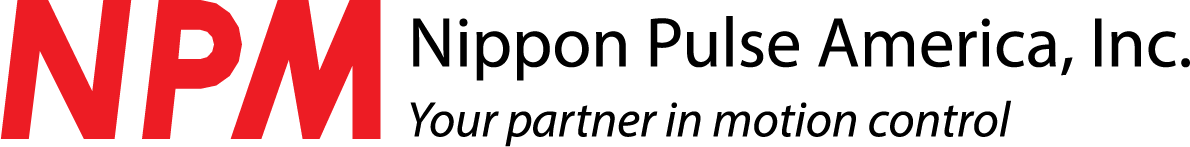

3 Axis Gantry Demo

Our 3-axis gantry demo is an example of the capabilities of a simple XYZ solution for various applications such as ultrasonic inspection, dispensing, or pick and place, etc.

The 3-axis gantry demo consists of 3 SLP15 linear shaft motor stages with 0.5 micron resolution encoders. Two parallel stages, operated from a single drive and feedback device carries the X axis stage. The X carries the Z axis stage which utilizes a linear shaft motor and gLess magnetic counterbalance. Our demo is set up with a Vermes dispensing head just give you some ideas on what can be carried by the stage. This could also be an ultra-sonic sensor or a pipettor or some type of probe – many options depending on the application requirements. This is such a simple design with the 3 stages outfitted with the 0.5µm encoder for sub-micron precision. The controller element is a custom PCB design under the control of the Commander Core – 4-axis controller and incorporating Arcus Titan cores for drivers. The unit has capabilities for linear, circular or helical interpolation and can operate on 48Vdc power. Speeds of 2 m/s and above are possible with acceleration rates of 3-5G’s or greater. Travel up to 2 – 3 meters with extremely smooth motion.

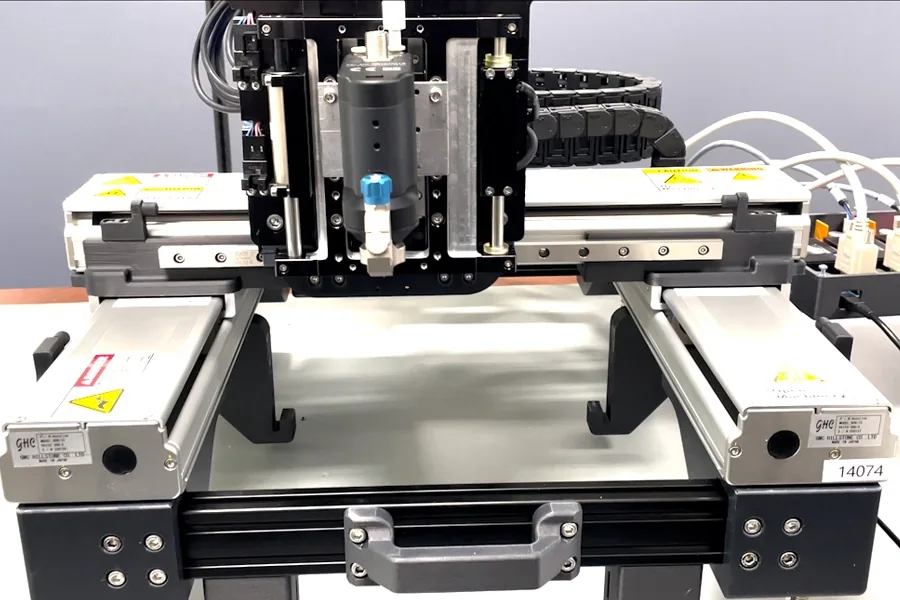

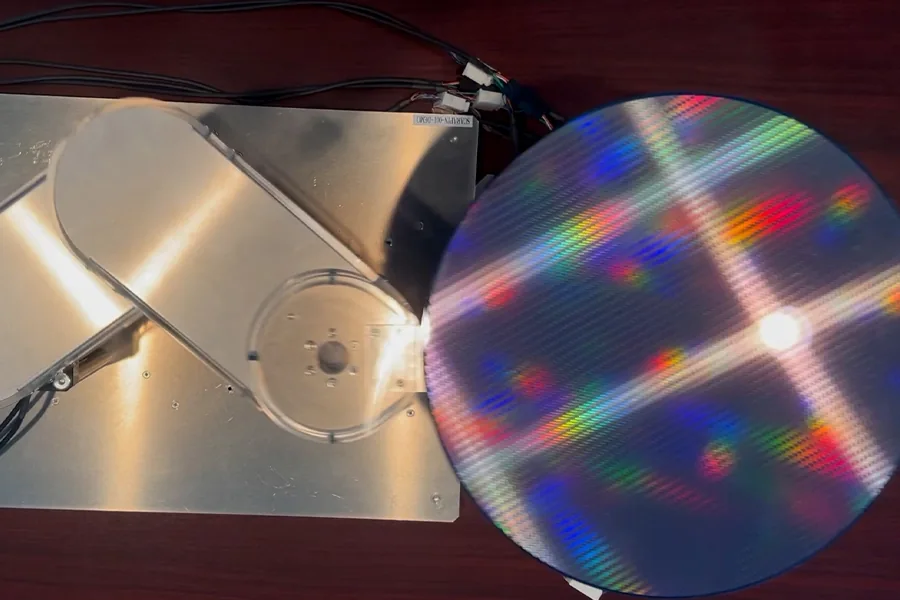

Wafer Transfer Solutions

Our wafer transfer mechanism illustrates 6 axes of motion under the power of our Micro Direct Drive motors.

Starting with the transfer mechanism itself, the see-thru construction provides a glimpse at the muscles underneath the enclosure. The base motor is a powerful MDH100 series direct drive servo motor. This product has the highest torque to size/weight ration of any similar product on the market. Motor construction and high-resolution absolute feedback provide the precision and power to rotate the upper extender arms. Each extender arm motor can be scaled in size as the carried load is reduced, thanks to the high-power density of the micro-direct drive motors (typically about 4 – 5 x the power density than similar motors). On the pin lifter axes, 3 small micro motors are couples with a lead screw to provide the coordinated lift of the wafer. The simplicity of this design eliminates gear reductions in the transfer mechanism and provides a light weight, precision mechanism to move wafers from one foup (front opening unified part) to the next (or any other transfer station or load lock). The micro direct drive motors are available with absolute or incremental encoders with resolution of 21 bits standard.

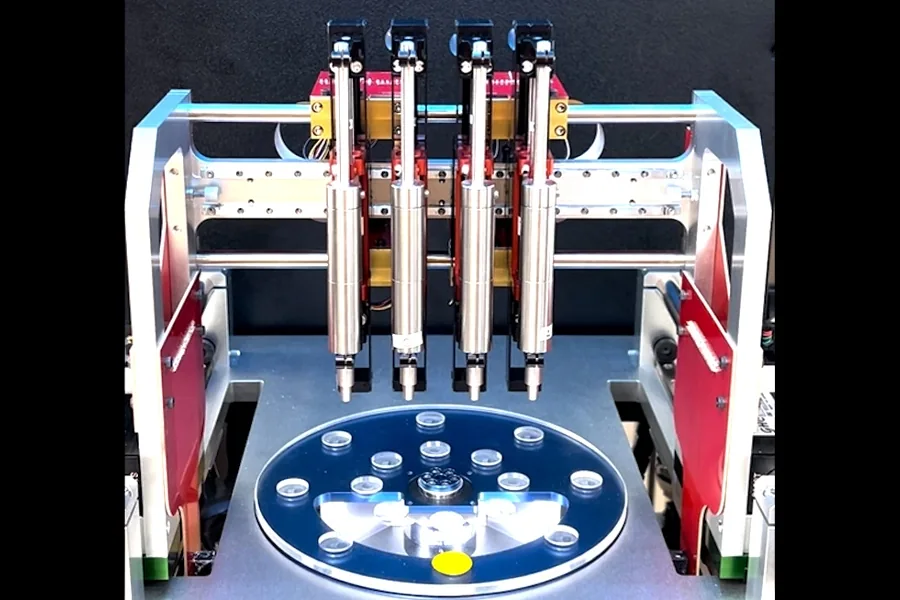

10 Axis Gantry Style Demo with Rotary Indexer

The 10-axis demo provides a glimpse into the power of the linear shaft motor and the Commander series controller in providing a coordinated dance of speed and precision.

Precision, speed, simplicity of design, and space savings are all on display in this unique configuration. The use of a single servo drive and feedback device to control the two parallel Y axes, simplifies set up and reduces the need for another driver. Multiple forcers on the same shaft on the X axes provide flexibility of control with independent movements of multiple Z axis devices. The slim Z axis linear shaft motors offer smooth control and are optimized with the use of our unique counterbalance solution. The rotary index table is controlled via a micro direct drive motor with 2,592,000 million counts per revolution. All linear motors are using integrated analog Halls (sin/cos) for feedback, simplifying the assembly and eliminating an external linear scale and read head.

All of the servomotors above (11 in all) move gracefully under the direction of the Commander core motion controller – 3 in fact. Each Commander is assigned to 3 axes of motion under the assistance of the compact MP3 Copley driver and the Y axis under the assistance of a Copley micro drive – the Nano, providing the capabilities for linear and circular interpolation, coordination of various I/O points, and synchronization of all axes. The custom PCB layout created for this demo is just one example of the capabilities to provide a compact controller/drive solution to minimize real estate on the machine. . Speeds of 2 m/s and above are possible with acceleration rates of 3-5G’s or greater. Travel up to 2 – 3 meters with extremely smooth motion even at slow speeds below 1mm/sec.