Services

Making Your Application Better

Customization for the Right Fit

Nippon Pulse America, Inc. and our partner companies provide our OEM customers with the ability to optimize their designs to produce the best results for their applications. This involves collaboration with design and manufacturing engineers to find the best solution – whether it’s the design of a custom winding to optimize voltage and current, or a modification of mechanical elements to optimize space, Nippon Pulse has the flexibility, using our standard products to build what our customers need.

Get the right fit!

Contact an applications engineer and get your collaboration started!

Editable Customization Worksheets

These editable worksheets will simplify and expedite the process of customizing products. Learn more and download here

Taking Performance to the Next Level

It starts with an idea, a desire to improve machine performance and take it to the next level. Our team looks over all possible solutions and then consults with your design team to make that idea come to life. A solution is identified, and trade-offs are reviewed – then the brainstorming, what if’s, and out-of -the box thinking settles in on the right product configuration. Prototypes are quickly built to prove out the design and put under rigorous testing. Results of testing are visited, possible design tweaks are initiated, and the solution is ready to be produced in quantities required at a competitive price.

Have questions? Want to talk through an application?

Give us a call at (540) 633-1677 or contact us.

Why Customize?

In today’s competitive marketplace – engineers are looking for that competitive edge – that extra speed, higher productivity, smaller footprint, higher efficiency, and on and on… Customizing can be a simple modification to a complete ground up design. Our approach covers this broad spectrum as shown below:

- Shaft and mounting modifications

- Cable length variation and termination options

- Alternate motor windings

- Special environmental considerations

- Higher level assemblies (Sub-assemblies)

- Special coatings or lubrication

- Ground up motor/drive development

Get Our Editable Customization Worksheets -

Learn more and download here >

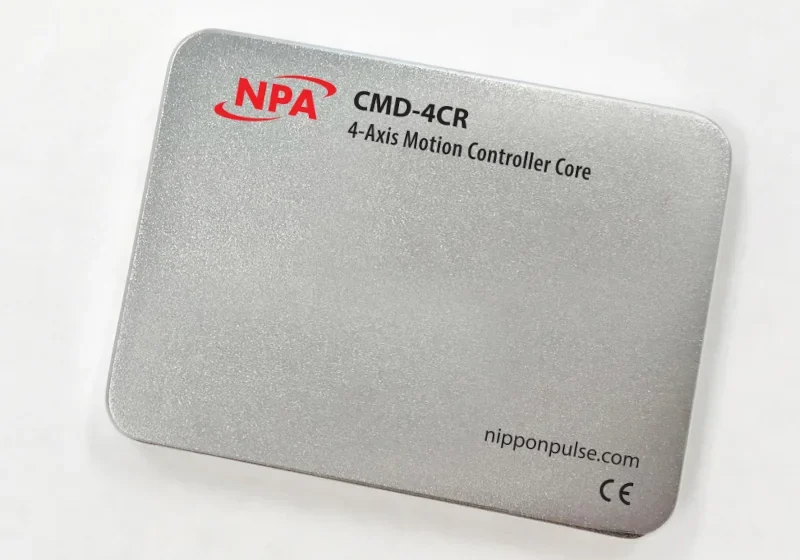

Custom Control Capabilities and PCB Development

Nippon Pulse America, Inc. also offers complete PCB customization for single and multi-axis control systems incorporating our Commander Core (CMD-4CR, CMD-8CR) and various core driver modules to operate various motor types. This capability is a cost-effective solution to customize your control system to meet your exact needs while minimizing space requirements.

From initial development to final PCB creation, the software/firmware that is part of the Commander solution is portable at each stage and can quickly be scaled up for higher production volumes.

Custom PCB designs can reduce cabinet space, reduce assembly time, and improve reliability.

For more information, contact our Engineering Department >

Need a prototype? We can help.

Nippon Pulse’s applications engineers work closely with each customer to understand their needs, then the Nippon Pulse model shop can produce a high-quality sample to specification. Give us a call at (540) 633-1677 or email our application engineers at [email protected] to find out more.