3 Reasons to Customize a Stepper Motor

By Bob White, Technical Sales Manager

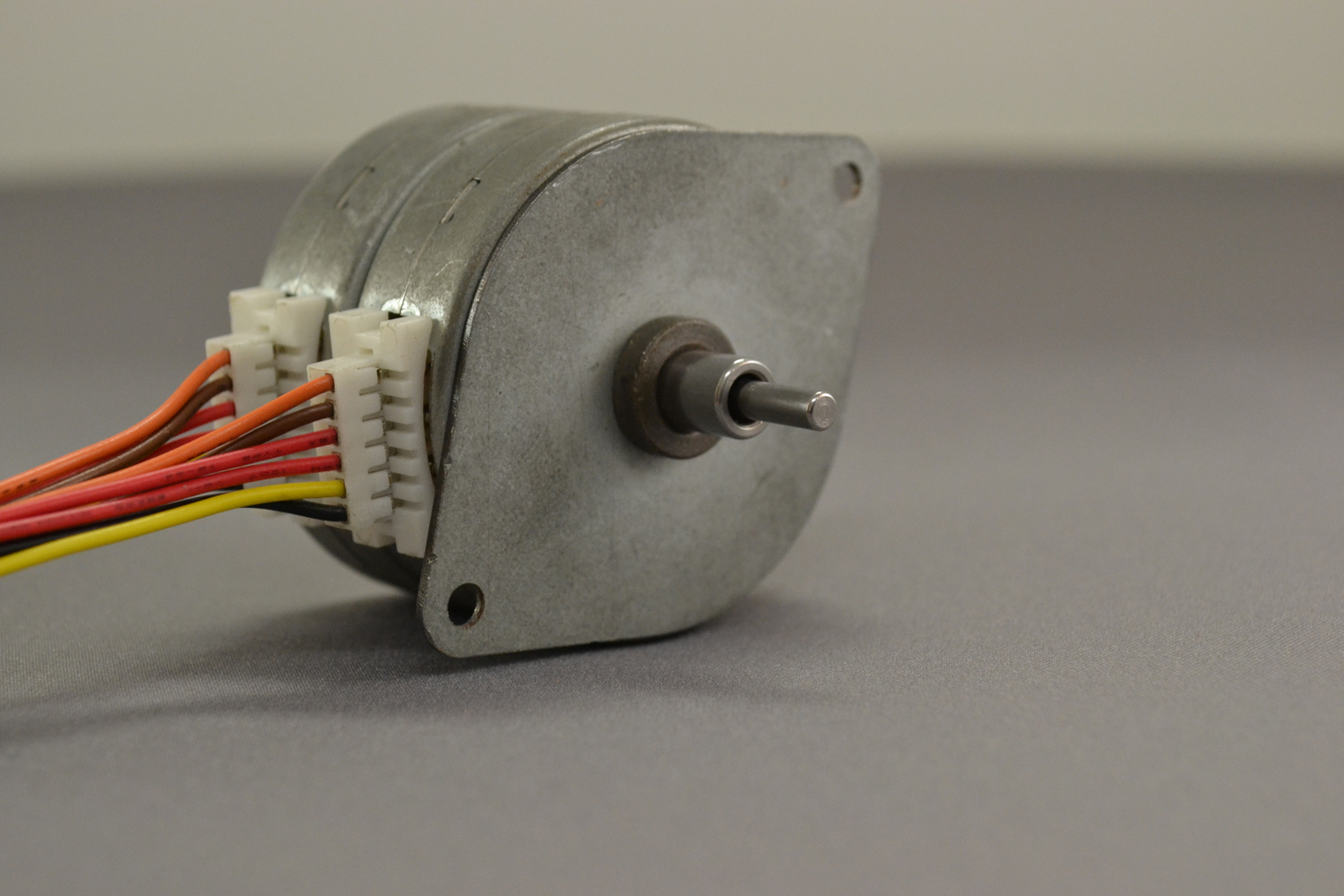

Step motors, especially tin can steppers, are typically considered commodity items – purchased by the millions and mass-produced around the world. In today’s competitive marketplace, a major factor for machine builders is still keeping costs low, but also ensuring a competitive advantage over other machine builders – that differentiator that will win the sale for their business.

Unfortunately, with mass production comes limited, if any, options. And machine builders in all sorts of industries are looking to minimize package size, reduce parts count, or otherwise find alternative ways to optimize their motion solutions, a critical means of achieving their competitive goals. Reaching that peak optimization may mean forgoing mass-produced motors, and instead looking at customization options.

Here are three reasons it makes sense to consider going custom.

The off-the-shelf motor doesn't fit into your machine's size or space constraints.

Making a motor fit in a tight space might lead you to looking at a custom mechanical configuration. Some customizations include a different shaft arrangement, the addition of a gear or pulley, or maybe an alternative cable or lead wire configuration to make the motor assemble into the machine more easily while meeting the required technical specifications.

You want your product design to outperform your competitors'.

Having a customized motor designed specifically for your application adds value, even if it costs a bit more than the off-the-shelf solution. However, any up front value-add costs really do benefit your business – in time and labor cost savings, improved productivity, or even meeting a key requirement/feature that sets you apart from your competition. And of course, if you can outperform or otherwise differentiate yourself from your competitors, the result is greater market share.

You need to guarantee the exclusivity of the motor design.

One other important consideration on customization ties into an OEM’s aftermarket success. When you find a company that will not only customize a product that meets your needs, but also protects your exclusivity to accessing that product, your aftermarket revenue stream is protected, extending the lifetime return on your machine design investment.

Very few companies in the step motor world are good at customizing tin can steppers, but a few really excel at it – not only can they assess your needs quickly, but also provide customization in a cost-effective and timely manner. Don't settle – make certain you get what you know will make your machine successful!

Contact Nippon Pulse's engineering team today to learn more about our customization capabilities or to get a quote for your project.